The dangerous exchange of bacteria and viruses from one food to another is cross contamination. Cross contamination is the cause for dozens of food recalls in the United States each year. Most of those incidents are reported to mainstream media. A massive food recall is an excellent way to taint a brand’s reputation.

Preventing cross contamination is a multi-step process. Some industries completely separate different foods. In contrast, many industries handle several foods in the same area, which requires an entirely new system for cross contamination prevention.

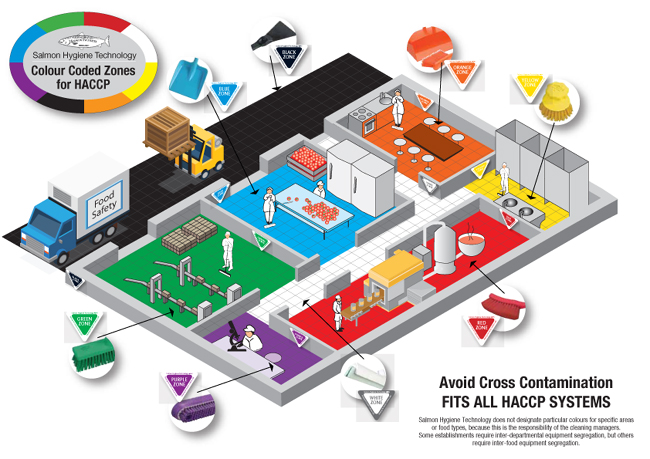

Salmon Hygiene Technology HACCP cleaning equipment is excellent for cross contamination prevention. The tools used in food departments concerned with cross contamination can designate color-coded control points for each job.

Choose a wide variety of HACCP cleaning products including shovels, brushes, dust mops, brooms, dustpans, and scrubs. Each of these products are available in eight different colors including green, blue, red, white, yellow, black, purple, and orange.

Each control point can include each of these tools and remain the same color. Different colors might signify different types of foods or uses. The management of the company can create a wide array of effective systems and uses of these color coded HACCP products.

‘Totally color coded cleaning equipment’ is the term used to describe completely color coded tools. For instance, the fill of a brush is the same color as the handle. Also, the handle of a shovel is the same color as the blade. This is an extra step to prevent cross contamination.

Another added benefit of the color coded system is the removal of any language barriers. Employees can identify colors much easier than multiple signs which can help avoid confusion. Many industry leaders utilize completely color coded tools which is vital to cross contamination prevention.

This graphic layout shows the versatility of this cross-contamination prevention system.

As you can see, these color coded control points will substantially reduce the risk of cross contamination. With every color representing an area, there is such a small margin for error, especially with properly trained employees. That is why these systems are becoming the industry standard.

What are you waiting for? Implement this system into your operation today.

Be sure to check back often for more tips on running a safer and more efficient warehouse!