Guide to Inline Pallet Inverter Systems – Video Transcript

Hello and welcome to Premier Handling Solutions’ video series on running a safer and more efficient warehouse. Today we’re going to be talking about all of the pallet inverters that can be integrated directly into your assembly line. These inline pallet inverters are fast, efficient, and great for continuous and automated systems.

Hello and welcome to Premier Handling Solutions’ video series on running a safer and more efficient warehouse. Today we’re going to be talking about all of the pallet inverters that can be integrated directly into your assembly line. These inline pallet inverters are fast, efficient, and great for continuous and automated systems.

What is an Inline Pallet Inverter

Depending on your needs, our entire line of pallet inverters can be modified to fit right in with the rest of your assembly line, making our already sterling pallet inverters work even more quickly and efficiently for you. They can help limit forklift and pallet truck use around your warehouse and can decrease manual labor and the time spent per project.

The FSDC Pallet inverter is the most common and versatile inline inverter, as its clamp opening will always be the same height, making it much easier to line up with your conveyor system. This makes it perfect for loads that are all similar like boxed wine for example, which needs to be inverted regularly to maintain moist corks.

You can even add a pallet dispenser just off the assembly line to feed new pallets into the inverter if pallets need to be switched (like changing from a wood pallet to a plastic pallet, for example).

The Recline and Rotate Pallet Inverters are also great for inline systems and are able to invert much larger and wider loads, like sheets of corrugated board. Pallet changers can also be modified to fit into your assembly line, and with a pallet stacker and dispenser, can easily switch out pallets from your loads.

The Recline and Rotate Pallet Inverters are also great for inline systems and are able to invert much larger and wider loads, like sheets of corrugated board. Pallet changers can also be modified to fit into your assembly line, and with a pallet stacker and dispenser, can easily switch out pallets from your loads.

With all of these inline pallet inverter systems, you can bypass loads completely if necessary, with the pallet inverter just letting the load continue down the line if told to. The inverters can all be right up against the conveyors as they rise from the conveyor line. All the inverters also require little extra space if they’re “turned off” and can have guards added around them easily.

At their peak, our inline inverter systems can invert a new pallet 180 degrees every two minutes and fit seamlessly into your current setup.

How Do Inline Pallet Inverters Work?

From the user’s perspective, there isn’t a whole lot you need to do to get an inline pallet inverter system operating smoothly, especially compared to using a more standard pallet inverter. Forklifts and pallet trucks are removed from the equation, so you just need to be proficient in using the buttons and levers to operate the inverter.

From the user’s perspective, there isn’t a whole lot you need to do to get an inline pallet inverter system operating smoothly, especially compared to using a more standard pallet inverter. Forklifts and pallet trucks are removed from the equation, so you just need to be proficient in using the buttons and levers to operate the inverter.

Simply let the conveyor bring your palletized load into the pallet inverter’s clamps, press a button or two and let the inverter work its magic.

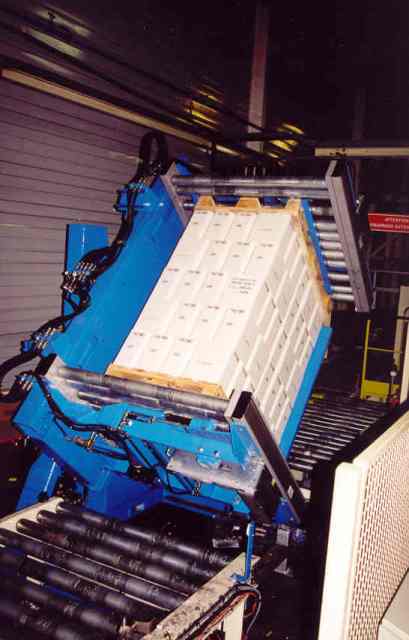

Here’s a video clip showing exactly how you can expect an inline pallet inverter addition to your warehouse to function.

As you just saw, the pallet comes in, gets held firmly in place, is inverted and then sent on its way to go through the rest of your assembly line. The previous pallet remains in the machine for the next pallet awaiting inversion.

Thank you for stopping by to watch the Premier Handling Solutions video series on running a safer and more efficient warehouse. Integrating pallet inverters right into your assembly line is still a relatively new technology, and specifications will depend on your current set-up, so inline pallet inverters are custom-built. Give us a call today and be sure to stop by often for more warehouse tips!