Warehouses to the common public are basically just settings for terrible things to happen in movies. What most don’t realize is the effectiveness of modern warehouses and the impact their design has on the cost of our goods. Decades of research has gone into strategically designing warehouses to be most efficient.

You might have read studies such as this one that shows how grocery stores strategically place items in their stores for maximum effectiveness. Placing essential items such as milk and bread at the back of the store results in consumers seeing more items; thus purchasing more than just milk and bread.

Warehouses are designed even more meticulously than grocery stores; due to the time and money-saving potential of certain layouts. For example, placing the loading dock and warehouse inventory on opposite ends of the warehouse will probably result in significantly reduced loading and unloading times. The longer it takes a forklift driver to load the truck, the higher it costs the warehouse to handle the goods; resulting in higher costs for the end user.

Six Main Objectives in Warehouse Design:

- Research and understand products being stored

- Does the product react poorly to moisture, bugs, etc.

- Anticipate problems

- A pipe could burst overhead and ruin inventory below.

- Develop warehouse flow path

- Avoid constant forklift and foot traffic interaction

- Establish facility requirements (loading dock, offices, creation, etc.)

- How many departments does your warehouse need? Where will they fit best?

- Make note of obstacles (columns, doors, different terrain)

- Use obstacles to your advantage when possible

- Maximize blueprint space

- Can’t expand outwards? Expand up!

Essentially, measuring space and maximizing material handling mobility is the name of the game. Mistakes happen, so warehouses will often take on too much of a product. This doesn’t have to be an incredible burden to a well designed warehouse. An agile warehouse will quickly transition from one product to another when necessary.

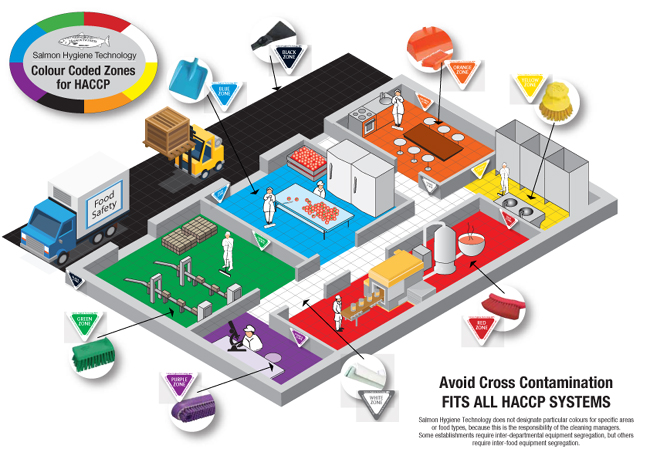

Safety is another concern. A packaging plant that handles food is especially susceptible to dangerous and costly mixups. Raw meats, when mixed will result in a warehouse making national news. To prevent such mishaps, internal systems such as HACCP and physical department placement within the building are essential to warehouse design.

Think shipping and handling costs are expensive now? Imagine a world without complex warehouse logistics. Our lifestyle would be much, much different.