Inline Pallet Inverter Systems:

Almost all of Premier’s Pallet Inverters can be integrated into an assembly line. Our Free Standing Pallet Inverter has even been installed with a conveyor on one table at the end of a line.

Almost all of Premier’s Pallet Inverters can be integrated into an assembly line. Our Free Standing Pallet Inverter has even been installed with a conveyor on one table at the end of a line.

The first pallet inverters set up for conveyor-feed were the GL style (no longer manufactured) which received the pallet load on one side and then swung over 180 degrees in an extended see-saw motion, to dispense it on the other. This was fine if every load needed to be inverted, but nothing could get through the machine without inversion, so it didn’t work for everything.

Another option for in-line inversion was our drum or “Pac Man” inverter. This pallet inverter featured electrically driven rollers underneath the body of the machine to invert loads. The pallet inverter itself was large and ineffective as it didn’t clamp and support loads as efficiently as we would have liked. This pallet inverter also fell out of favor.

The Inline FSDC Pallet Inverter:

The FSDC pallet inverter is much more suitable for in-line systems. This pallet inverter is extremely versatile and is the most common inverter added to assembly lines.

FSDC Pallet Inverter Advantages:

- The pallet inverter’s dual clamping tables open to the same height every time which keeps it aligned with the conveyor.

- The pallet inverter’s sidewall naturally stops the incoming load and pallet gripping systems can easily be implemented on the conveyor.

- The pallet inverter requires very little “off-line” space when not in use and is easy to guard.

- The FSDC pallet inverter can be custom built for various applications but systems in which the loads are very similar and require inversion are the ideal applications. Examples include boxed wine which has to be turned 180° to keep corks moist and stacks of corrugated board in the carton packaging industry.

Exchanging pallets as a part of the assembly line’s operations can also be achieved by implementing a pallet dispenser that feeds pallets from just off the line. When a load passes along the conveyor that does not need to be inverter, the sidewall can open hydraulically to allow the pallet to pass through.

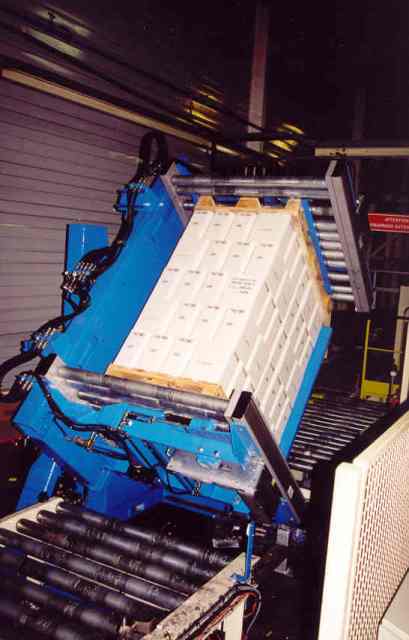

The Inline RR Pallet Inverter:

The RR pallet inverter is the solution to many problems that are associated with inline pallet exchanging.

- The loading tables can be custom built to any size and our extensive clamping range is ideal for handling large sheets of corrugated board.

- Loads that do not need inverted can simply pass through.

- The RR pallet inverter clamps the load and rises immediately out of the conveyor line. This allows adjoining rollers to butt up against those on the inverter tables.

The Inline Pallet Changer:

Future in-line systems will undoubtedly be based on the Pallet Changer principle.

- This pallet changer can be loaded from the front or side onto roller lifters that are fitted to the machines loading table.

- A pallet stacker and dispenser are integrated in the system and used to eject and load the pallets.

- The Pallet Changer works “off-line” allowing goods which do not need transfer to pass straight by

- Product is returned to the upright position on a new pallet.

Inline Pallet Changer Video:

Conveyor fed pallet inversion is a relatively new concept and is continuously growing. The inline Pallet Inverter system is not ideal for every warehouse. Most applications would be better suited using a conventional inverter due to a wide range of load shapes and sizes. However, for consistent loads that can be handled using a conveyor system, the Inline Pallet Inverter system is the best option.