G95 Pallet Inverter Specs:

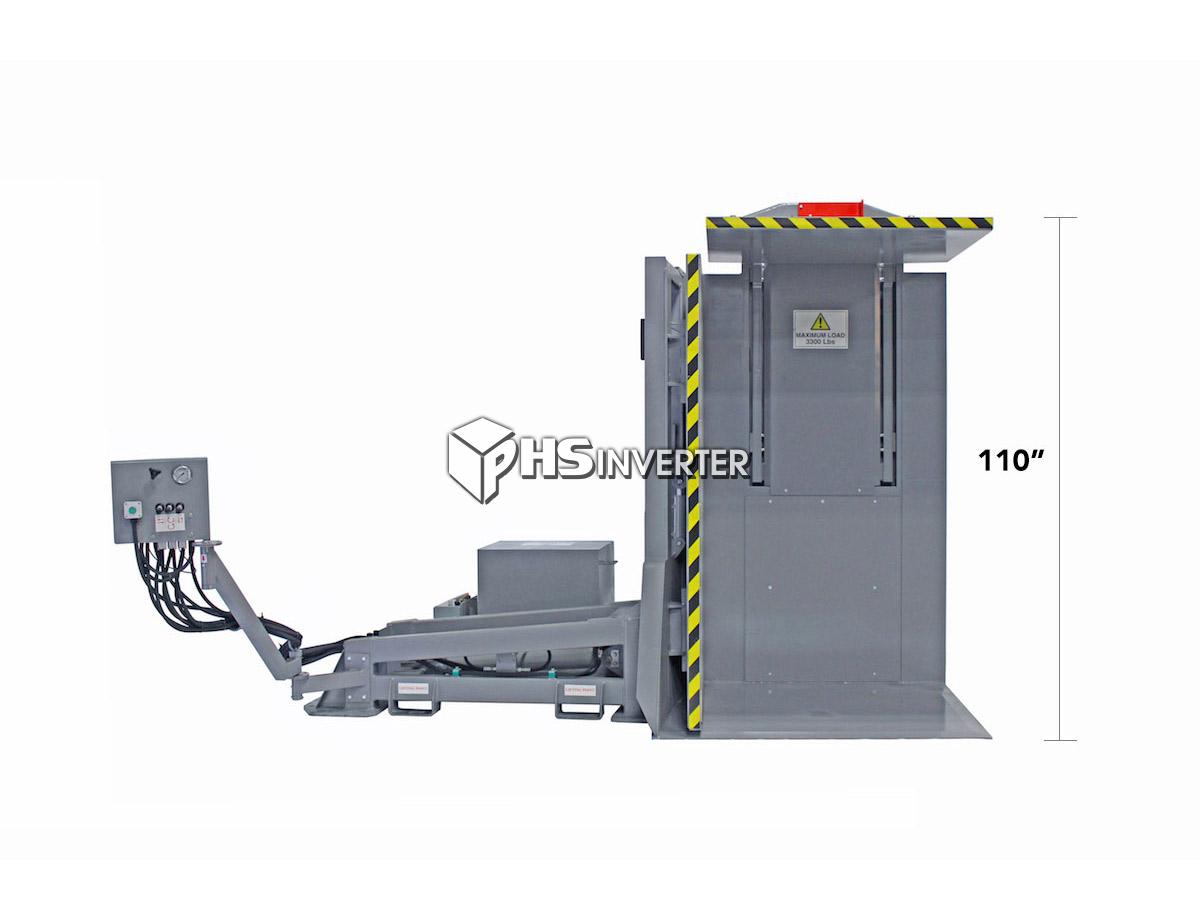

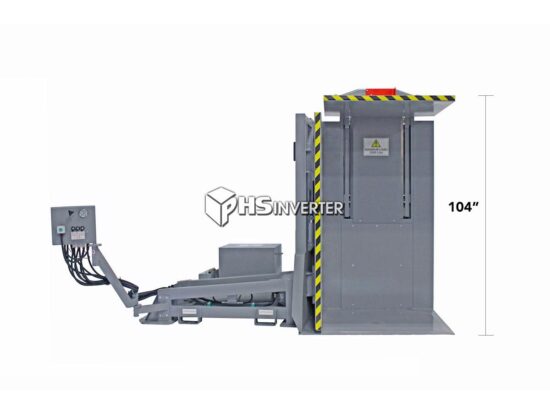

| Jaw Opening | Max 110″ – Min 62″ | |

|---|---|---|

| Capacity | 4,400 lbs | |

| Loading Tables | 51″ x 51″ | |

| Controls | Lever / Push Button | |

| Power | 3ph / 208,230,460,575V | |

| Finish | 2 Part Epoxy Acrylic Top Coat | |

| Color | Machine Gray | |

| FOB | Elgin, IL 60123 | |

G95 Pallet Inverter Industries Served:

The G95 Pallet Inverter /Freezer Spacer Removal System:

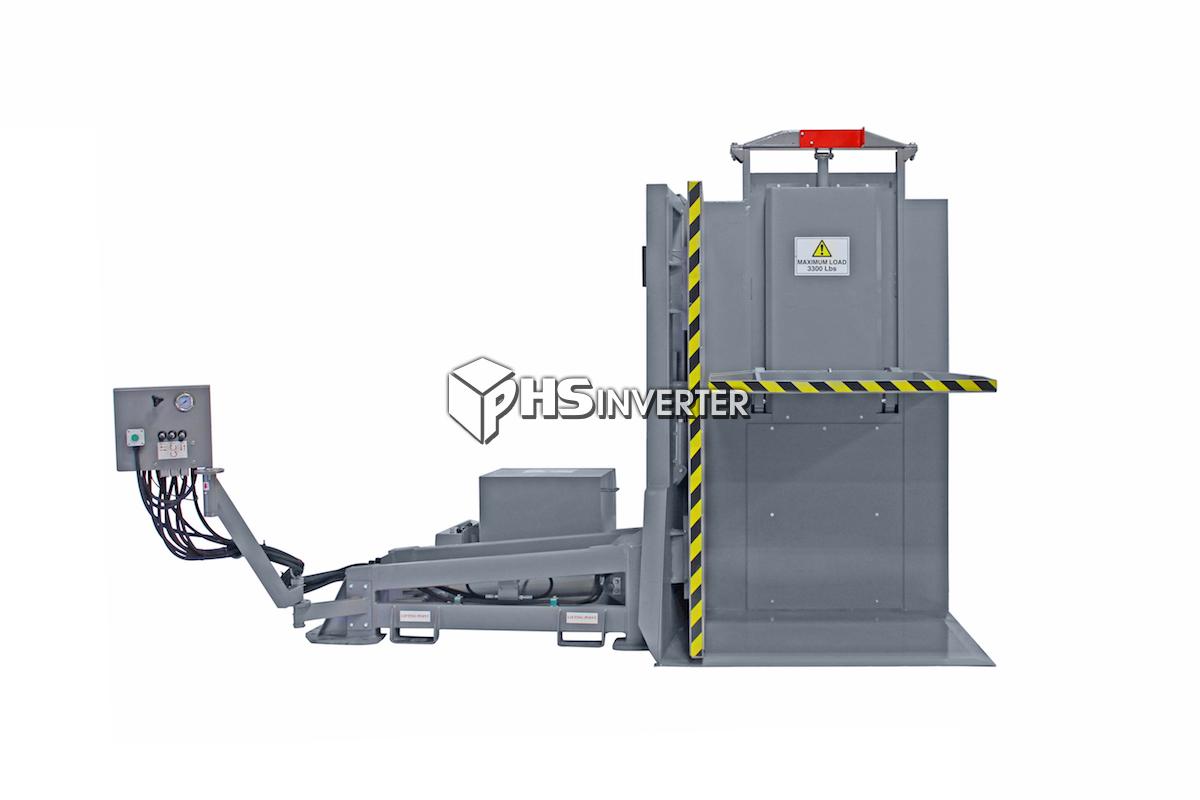

The G95 Pallet Inverter or Pallet Retriever style of transfer system was first developed in the mid 1980’s for use in cold storages, blast freezing warehouses or distribution related facilities exporting product. It was designed as an alternative to the conventional 180° Pallet Inverter, which did not offer ground loading or pallet separation capabilities at the time which later became an industry standard. With that, the G95 Pallet Exchange / Pallet Retriever was developed.

The G95 Pallet Inverter Primary Uses:

- Recovery of broken pallets

- Simple transfer or exchange of in house or export pallets

- Faster removal of blast freezing spacers, slats, or dividers

- Reduce labor and eliminate lumping service needs

- CHEP, IGPS, PECO or other rental pool handling flexibility

Today these pallet inverters and exchanges are used in the following industries:

- Cold Storages / Blast Freezing Facilities

- Distribution Centers

- 3rd Party Logistics

- Meat, Poultry, Pork and Seafood Processing Facilities among others

- Regional Mixing Centers

- And many more

As with all of the Premier Equipment, it incorporates a robust steel construction particularly suitable for the harshest environments including 24/7 operations pulling spacer dividers or exchanging pallets.

By tipping the load on its side just beyond 90° it allows the load to rest on the skate table or side wall. When the clamp is released from the top of the load it will allow the product to glide away from the pallet or load table enabling quick simple and safe pallet transfer, replacement or freezer blasting slat removal.

HOW IT WORKS

When Removing Freezer Spacer/Slats or Blast Freezing Dividers:

- Load is placed in G95 Pallet Inverter / Pallet Retriever at ground level

- Load is clamped to secure the product as needed

- Load inverted from the ready position to 95º

- Load unclamped

- Product will then pull away from the load table via gravity / powered skate table

- Blasting Divider / Freezer Slats are then removed at comfortable working height

- Load is clamped

- Load is then inverted back up to the ready position

- Load is unclamped

- Load is removed

When Transferring or Exchanging In-house, Export, or Rental Pallets:

- Load is placed in G95 Inverter at ground level

- Load is clamped to secure the load as needed

- Load inverted down to horizontal position

- Load unclamped

- Old pallet is removed by hand and the new pallet is inserted by hand

- Load clamped to secure the load

- Load is then inverted back up to the ready position

- Load unclamped

- Transferred or Exchanged load is ready for long term storage or shipment staging