90° Roll and Pallet Tippers:

Premier specializes in hydraulic 90° tipping systems which can handle 1,100 to 33,000 lbs. The tippers can be custom built to the size and weight of your loads and specific methods of material handling. The most common uses of our 90° tippers involve upending paper rolls and steel coils for processing and to suit delivery or storage requirements. Three base styles of our tippers can be customized to fit your needs.

As a standard we offer 3 different Pallet Tipper styles:

- Type 1: This tipper is loaded from a raised position and tips to ground level, or vice versa. Paper coils are easily rolled off at floor level after the tipping process.

- Type 2: The type 2 is best suited for heavier loads where its design can cater for increased ram power. It loads and discharges at a raised height by forklift or overhead hoist.

- Type 3: Our most popular unit tips to floor level on both sides without needing to construct a pit. One of the tables turns flush to the floor and the other is approached by a ramp. This type of tipper can handle loads up to 2,750 lbs.

90° Roll and Pallet Tipper Uses:

- Tip paper reels onto their side before unwinding

- Turn steel coils to ‘core vertical’ so they are ideal for loading on a pallet and transportation

- Turn large and heavy objects in the maintenance or production program

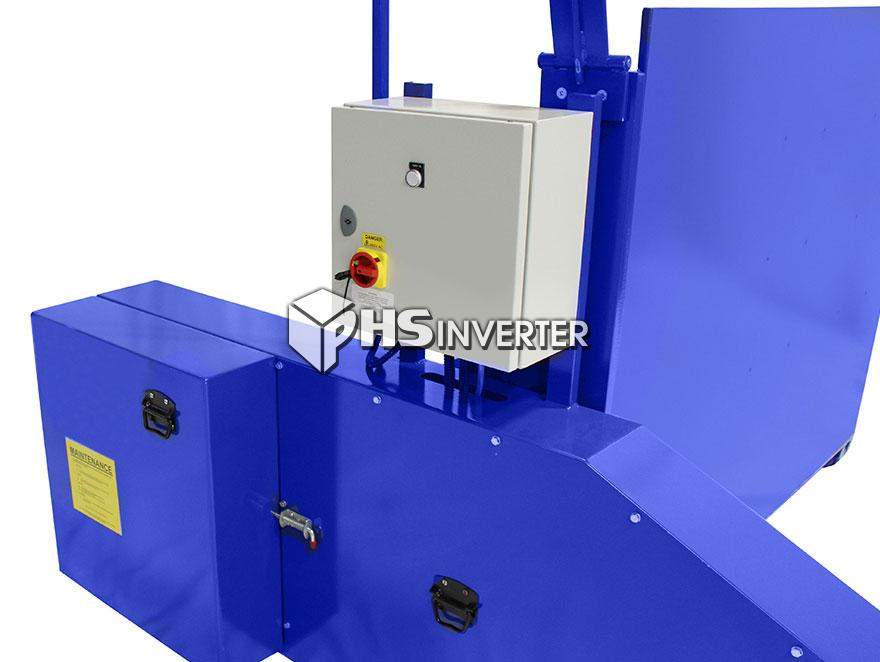

90° Roll and Pallet Tippers Key Features:

- Hydraulic self-contained power pack

- 33,000 lb. load capacity

- Remote push-button pendant control

- Simple, safe, and effective

- Heavy duty construction with high overload protection

- Simple, safe and effective